Electrodes

There are two types of electrodes and the choice depends upon specific applications, and the material being treated.

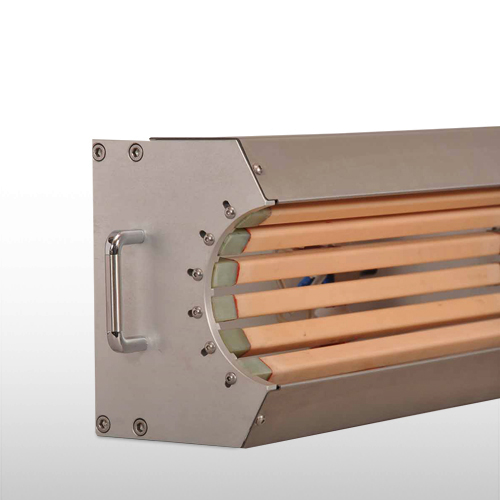

METAL ELECTRODES

In metal electrodes, the extrusion process is not restricted by the conductive materials – giving a greater choice of electrodes. Usage of fixed width or segmented electrodes made from aluminium or stainless steel depends upon the widths that the film manufacturer is producing. Most film manufacturers prefer using segmented electrodes, as it allows them to run their extrusion lines for a longer period of time without modifying the Corona Treatment system.

Types of Metal Electrodes:

• Fixed Type Electrodes

• Segmented Electrodes

• Round SS Electrode: 12mm OD x 8mm ID

CERAMIC ELECTRODES

Ceramic electrodes offer the flexibility to treat conductive and non-conductive films, but are rarely used in extrusion blown film or cast film lines. The most common application of ceramic electrodes is converting lines where more flexibility is required to treat a variety of materials. Ceramic electrodes are fixed length electrodes and cannot be configured in segmented form. They require proper cooling as the chances of breakage increase due to overheating. Hence proper heat/ozone extraction is vital in this configuration.

Types of Ceramic Electrodes:

• Slot type Ceramic Electrodes Exclusively Designed for IEEC Corona Treater

• Square Ceramic Electrodes: 15mm x 15mm